Discover the reasons behind bearings needing a little extra care and attention. In this insightful article, we’ll delve into the challenges bearings face, explore repair options, and highlight the importance of regular maintenance for optimal performance.

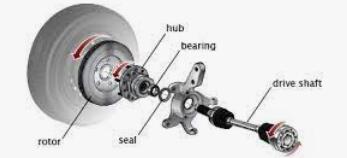

Bearings are crucial in many mechanical systems, enabling smooth motion and minimizing friction between moving parts. However, bearings may experience problems that can impact their efficiency and longevity as time goes on.

Why Did the Bearing Seek Therapy?

Much like any other mechanical component, Bearings can benefit from therapy to address issues like wear and tear, lubrication problems, and misalignment. When bearings experience unusual sounds, excessive friction, or irregular wear patterns, it’s a sign they need attention.

In this article, we will dive deeply into the common issues bearings face, explore the signs indicating that a bearing needs service, and examine the various repair and replacement options. We’ll also highlight the importance of regular and timely maintenance to ensure bearings remain in optimal condition.

Additionally, we’ll add a bit of humor by discussing the role of lightheartedness in engineering and technical fields, making the topic both informative and entertaining.

Typical Issues Encountered by Bearings

Indicators of Wear and Damage:

Bearings are subjected to constant stress and pressure throughout their operation, which causes them to wear out over time gradually.

Several factors, including excessive loads, high speeds, insufficient lubrication, and demanding operating environments, accelerate this wear.

If bearings are used for extended periods without adequate maintenance, their functionality may deteriorate, potentially leading to system failure.

Issues with Lubrication:

Proper lubrication is essential for minimizing friction and preventing excessive heat buildup within bearings.

However, insufficient lubrication, the presence of contaminants in the lubricant, or the degradation of the lubricant can result in higher friction, speeding up wear and increasing the risk of bearing failure.

Additionally, inadequate lubrication makes bearings more susceptible to corrosion and damage from external contaminants.

Problems with Alignment:

Correct alignment of bearings within their housing is essential for achieving optimal performance. Misalignment, which can occur due to installation mistakes, system vibrations, or external forces, leads to uneven loading, increased wear, and the potential for early bearing failure.

Misalignment can also result in higher friction, excessive heat buildup, and damage to surrounding components.

Indicators That a Bearing Requires Service

Strange Noises or Vibrations:

Any odd noises from the bearing, such as grinding, squealing, clicking, or rumbling, often point to potential issues. Furthermore, excessive vibrations or shaking during operation can indicate that the bearing is under strain.

These warning signs indicate that the bearing suffers from increased friction, misalignment, or other hidden problems.

Excessive Friction or Heat Production:

When bearings encounter issues, they may experience higher friction, which leads to increased heat generation.

This can be noticed through elevated temperatures around the bearing area or by feeling the surface directly.

Excessive heat can cause lubricant degradation, hasten wear, and potentially lead to system failure. Regularly monitoring temperature fluctuations during operation is key to spotting potential bearing problems.

Unusual Wear Patterns:

Consistent bearing inspection is crucial for detecting unusual wear patterns. Indicators of concern include pitting, galling, spalling, or brinelling on the bearing surfaces.

These irregularities point to possible issues that must be addressed to prevent further damage. Tracking wear patterns also helps uncover underlying problems like misalignment or lubrication issues.

Choices for Bearing Repair or Replacement

Bearing Cleaning and Lubrication:

Bearing problems can be addressed in certain situations with effective cleaning and appropriate lubrication.

Cleaning eliminates contaminants that may have infiltrated the bearing, which can negatively impact its performance.

Fresh lubrication helps minimize friction, ensures smooth operation, and safeguards against wear and corrosion.

Maintaining regular maintenance routines can help pinpoint when cleaning and lubrication are necessary.

Re-greasing Bearings:

When a bearing remains in good condition but suffers from inadequate lubrication, re-greasing can help restore its functionality. The re-greasing process involves removing the old grease and applying a fresh, appropriate amount to ensure proper lubrication.

This procedure replenishes the lubricant, lowers friction, and improves the bearing’s capacity to handle heavy loads and high speeds.

Replacing Components:

Replacement may be required when a bearing experiences significant wear, damage, or misalignment. This usually involves removing the damaged bearing and installing a new one, ensuring proper alignment and lubrication.

Replacing the component is essential to restore the bearing’s performance and prevent additional damage to the equipment.

Importance of Quick Bearing Maintenance

Optimized Performance and Efficiency:

Consistent maintenance, including timely repairs and replacements, helps keep bearings functioning at their best. By promptly addressing bearing issues, friction and wear are reduced, which enhances the overall performance and energy efficiency of machinery or equipment.

Lower friction also results in decreased energy usage and boosts productivity.

Enhanced Equipment Longevity:

Properly maintained bearings greatly extend the life of the equipment they comprise. Addressing problems quickly reduces the chances of significant failures and expensive repairs or replacements.

Routine maintenance, such as cleaning, lubrication, and timely repairs, helps maintain the bearings’ integrity and protects other components in the system from damage.

Minimize Downtime and Maintenance Costs:

Proactive bearing maintenance helps prevent unexpected failures and reduces downtime by addressing potential issues before they worsen.

By detecting and resolving bearing problems early, the need for expensive emergency repairs is minimized, leading to less downtime and fewer production losses.

Scheduled maintenance, including regular inspections and timely repairs, is typically more cost-effective than reacting to problems as they arise.

Humor in the World of Engineering and Technology

Examples of Engineering Humor:

1.”Why did the bear visit a therapist? It couldn’t cope with the weight of its emotional load!”

2.”Why did the bearing bring a pillow to work? It was looking to take a break and reduce the friction in its life!”

3.”Why did the bear go to the comedy club? It needed to roll with laughter and ease some axial tension!”

4.”Why did the bear start practicing yoga? It wanted to find its inner alignment and embrace the true race!”

5.”Why did the bearing join a band? It was all about the rhythm and ‘rolling’ beats!”

6.”Why did the bear become a detective? It was determined to solve the mystery of the strange vibrations!”

7.”Why did the bearing throw a party? It was celebrating its smooth operation and radial success!”

8.”Why did the bearing begin a fitness routine? It wanted to boost its endurance and never run out of ‘bearings’!”

9.”Why did the bear go on a vacation? It needed a break from constant rotation and wanted to ‘roll’ in the sand!”

10.”Why did the bear start a motivational blog? It aimed to inspire others to keep rolling, no matter the challenges!”

These jokes are a lighthearted way to add humor to bearings and engineering. They are designed to bring a smile to the faces of those familiar with the technical details of bearings and the work that goes into them.

The Importance of Humor in the Workplace:

Humor is vital in reducing stress and building strong relationships among team members, particularly in engineering and technical environments.

By easing the tension that comes with challenging projects, humor can stimulate creative thinking, encourage innovative solutions, and contribute to a supportive atmosphere where productivity and teamwork thrive.

Final Overview:

Identifying common bearing problems, recognizing early warning signs, and promptly attending to maintenance requirements are crucial to ensuring mechanical systems’ smooth operation and extended life.

Professionals can minimize downtime, lower costs, and enhance equipment longevity by adopting proactive bearing maintenance strategies.

Moreover, incorporating humor into the engineering and technical fields brings a lighthearted element to the challenging nature of the work, fostering a positive and enjoyable workplace culture.